Efficiency, service life and system integration in real-world operation

The Safa Tempos operating in Kathmandu are among the world’s earliest electric vehicles deployed on a large scale in public transport. Since the mid-1990s, they have been in daily operation, transporting hundreds of thousands of passengers emission-free through one of South Asia’s most heavily polluted cities. For many years, however, this system relied on lead-acid batteries – a technology that increasingly limited long-term, economically viable operation.

With the REPIC project “Market Launch of Lithium Batteries for Electric Vehicles in Nepal”, a fundamental technological step was taken from 2016 onwards: the systematic conversion of Safa Tempos to lithium iron phosphate (LiFePO4) batteries under real operating conditions.

REPIC is an interdepartmental platform of the Swiss federal offices SECO, SDC, FOEN and SFOE. This funding contribution initiated the conversion of the Safa Tempos. In addition to the development work for the conversion, the grant also financed the actual conversion of the first three vehicles and partially that of the subsequent seven vehicles.

Thomas Kuster of Ingenieurbüro Kuster contributed significantly to the successful implementation of this project.

Initial situation: Technical limitations of lead-acid batteries

The lead-acid batteries originally used were only partially suitable for intensive daily operation:

- Very high battery weight

- High maintenance requirements

- Short service life, typically 12–15 months

- High energy losses during charging and discharging

- Increasing downtime and declining economic performance

These factors not only led to rising operating costs, but also posed a long-term threat to the viability of the entire transport system.

Technological approach: Lithium iron phosphate as part of an integrated system

The project deliberately did not pursue a simple battery replacement, but rather a system-based approach. The introduction of lithium technology was implemented in combination with:

- A professional Battery Management System (BMS)

- Adapted charging infrastructure

- Optimised integration into the existing vehicle architecture

- Training for drivers and workshops

- Replacement of additional components, such as the introduction of asynchronous drives, a rear axle with integrated motor, speed reduction and differential

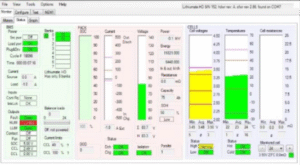

| Testen von Batterien, Cell Boards, BMS controller | Graphical User Interface GUI Menu: Monitor / Status |

|

|

LiFePO4 cells were selected due to their high thermal stability, long service life and robustness in daily operation – decisive criteria for vehicles without climate-controlled garages and with high daily mileage.

Measurable results in everyday operation

The results of the conversion demonstrate clear technical and energetic advantages:

- One lithium battery set replaces two lead-acid battery sets

- Energy consumption per loop (route):

– Lead-acid: Ø 6.6 kWh

– Lithium: Ø 2.8 kWh

→ more than 50% energy savings - Daily range of up to 120 km without intermediate charging

- Expected battery service life: 6–7 years

(already exceeded by the first converted vehicles by the end of 2025) - Significantly reduced battery weight

- Reduced mechanical wear on chassis and drivetrain

- Higher vehicle availability due to lower maintenance requirements

These figures were achieved not in laboratory conditions, but in demanding daily operation within Kathmandu’s urban traffic.

Energy efficiency and sustainability

The increased efficiency of the lithium batteries has a direct impact on environmental performance and resource use:

- More than 50% lower electricity consumption per kilometre driven

- Reduced charging losses

- Longer battery service life conserves raw materials and embodied energy

- Nearly emission-free operation, as approximately 95% of Nepal’s electricity comes from hydropower

- The first batteries installed in 2017 are still in operation at the end of 2025

- Batteries are no longer discarded, but given a second life

| Mounting of batteries | Technician Anil checking the battery condition |

|

|

In combination with modern AC drive systems, the converted Safa Tempos are now among the most energy-efficient forms of public transport in Nepal.

Economic efficiency over the life

Although lithium systems involve higher initial investment costs, operational data clearly demonstrate their economic superiority:

- Significantly lower cost per kilometre

- Fewer battery replacement cycles

- Lower maintenance and repair costs

- No need for midday battery changes

- Higher daily vehicle utilisation

- Conversion costs can be amortised within approximately three years

Over the full life cycle, lithium batteries are clearly more cost-effective than lead-acid systems. This is particularly important for drivers with limited capital and enables stable, predictable incomes.

Scaling and market introduction

The project was deliberately designed as a market launch under real market conditions. Following the successful testing of the first vehicles, the technology was rapidly adopted and disseminated independently. Today, almost all 650 Safa Tempos operate with lithium technology, without further external project funding.

This demonstrates that modern battery technology is technically manageable, economically viable and sustainable in long-term operation, even in a developing-country context.

Significance for future vehicle generations

The successful introduction of lithium batteries provides the technological foundation for further development steps:

- New vehicle generations

- Modernisation and innovation programmes

- New lightweight and modular design concepts

- Improvements in safety, energy efficiency, comfort, stability and service life

- Strengthening of the Nepalese electric vehicle market, with the domestic vehicle industry offering a superior solution to lead-acid batteries

- Improved prospects for the long-term survival of the Safa Tempo system

- Local manufacturing and maintenance

It thus represents a key building block for securing the long-term future of the Safa Tempo system and for sustainable electric mobility under demanding conditions.